Stainless Steel | SS201,SS301,SS303, SS304, SS316, SS416 etc. | |||

Steel | mild steel, Carbon steel, 4140, 4340, Q235, Q345B, 20#, 45# etc. | |||

Brass | HPb63, HPb62, HPb61, HPb59, H59, H68, H80, H90 etc. | |||

Copper | C11000,C12000,C12000, C36000 etc. | |||

Aluminum | AL6061, Al6063, AL6082, AL7075, AL5052, A380 etc. | |||

Iron | A36, 45#, 1213, 12L14, 1215 etc. | |||

Plastic | ABS, PC, PE, POM, Nylon, PP, Peek etc. | |||

Stainless Steel | Polishing, Passivating, Sandblasting, Laser engraving |

Steel | Zinc plating, Oxide black, Nickel plating, Chrome platingk, Carburized, Powder Coated |

Aluminum parts | Clear Anodized, Color Anodized, Sandblast Anodized, Chemical Film,Brushing,Polishing |

Plastic | Plating gold (ABS), Painting, Brushing (Acylic), laser engraving |

Agricultural equipment | Computing equipment | Automobile industry | Armament |

Medical / dental instruments | Measuring instruments | Miscellaneous equipment | Textile equipment |

Pharmaceutical industry | Pumps and general connections | Petrochemical industry | Safety equipment |

Industrial valves | Fixing and movable equipment | Pharmaceutical industry | General machinery |

Orthopedic implants | Food and beverage processing | Instrumentation equipment | Sanitary fittings |

or just an idea. control of non-standard products and OEM products.

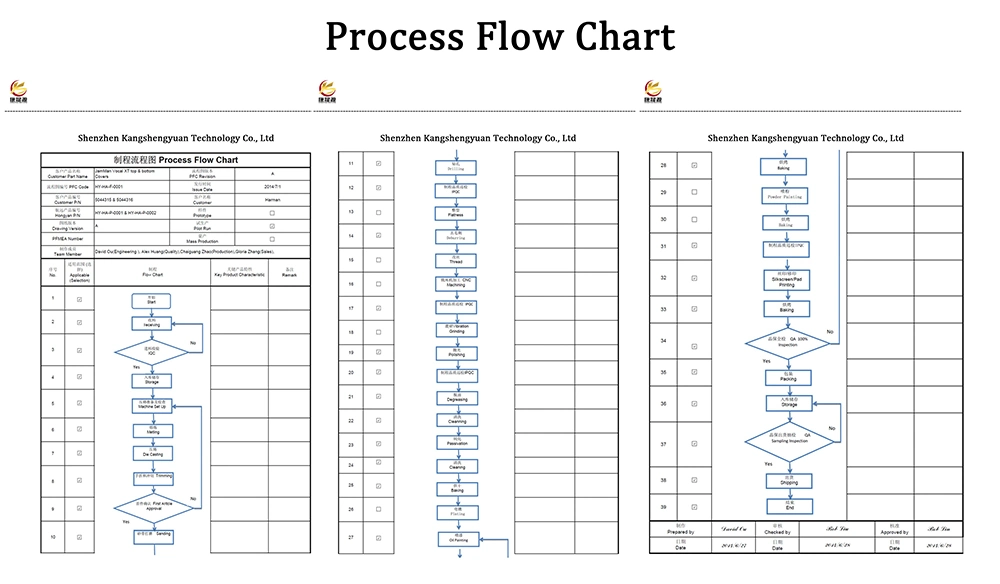

5, Quality Control

1) Checking the raw material after they reach our factory------- Incoming quality control ( IQC)

2) Checking the details before the production line operated

3) Have full inspection and routing inspection during mass production---In process quality control(IPQC)

4) Checking the goods after they are finished---- Final quality control(FQC)

5) Checking the goods after they are finished-----Outgoing quality control(OQC)

Founded in 2005, Shenzhen kangshengyuan Technology Co., Ltd is a manufacturer with more than 10 years experience of moulds, die casting and CNC Precision machining parts and follow-up process located in Shenzhen, China.

The factory covers an area of over 10,000 square meters and has a construction area of over 5,500 square meters. We have more than 200 employees and over 30 professionals.

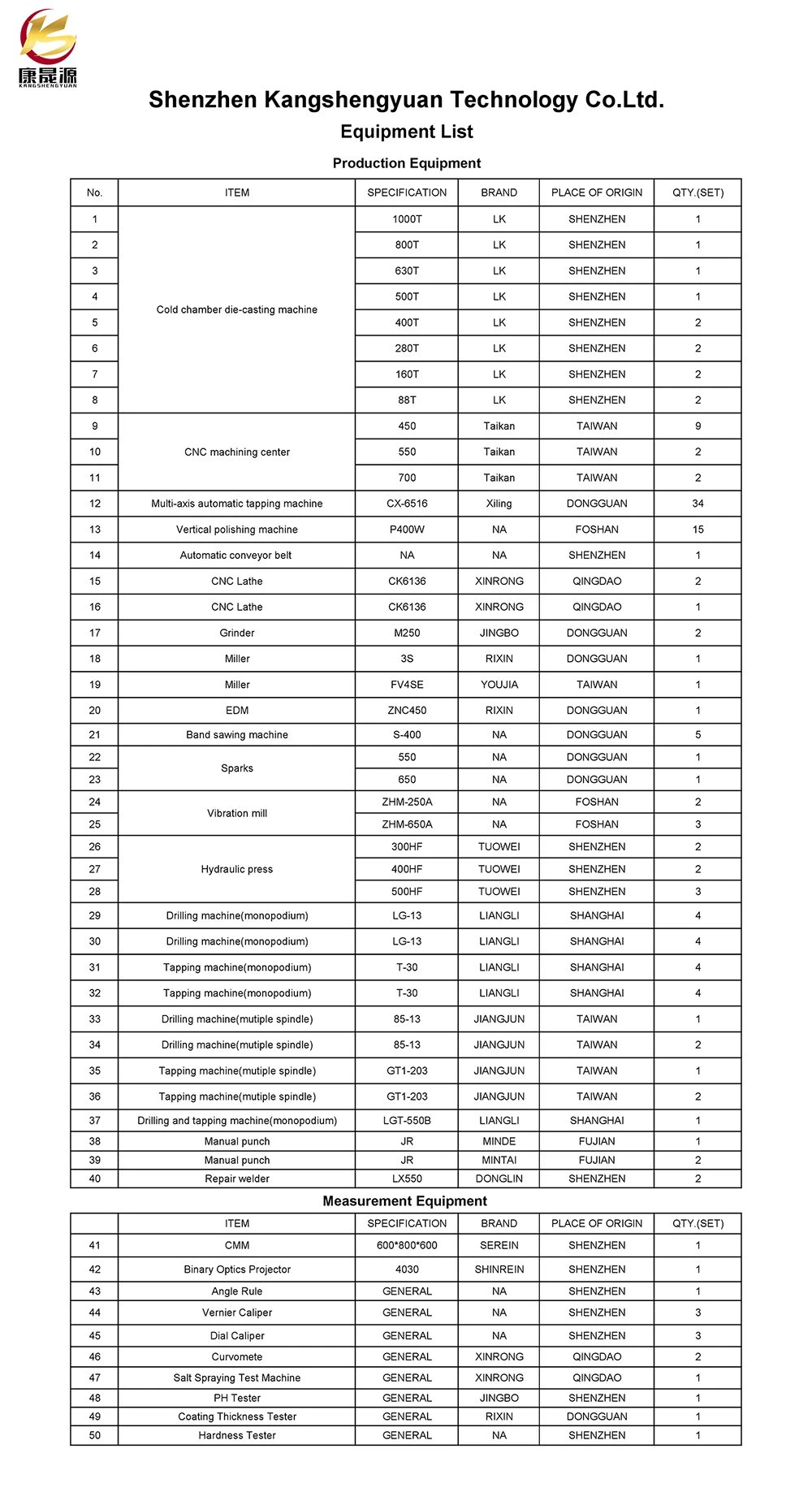

Insisting on advancing with times with reform and innovation and always committed to producing high quality products. We develop a team of over 30 talents focusing on mold design and manufacturing. The factory is equipped with all kinds of high precision machines, offering one-stop services from mold design to shipment.

Our service

We look forward to working with you to create a better future.

Our advantage:

- An experienced mold design team

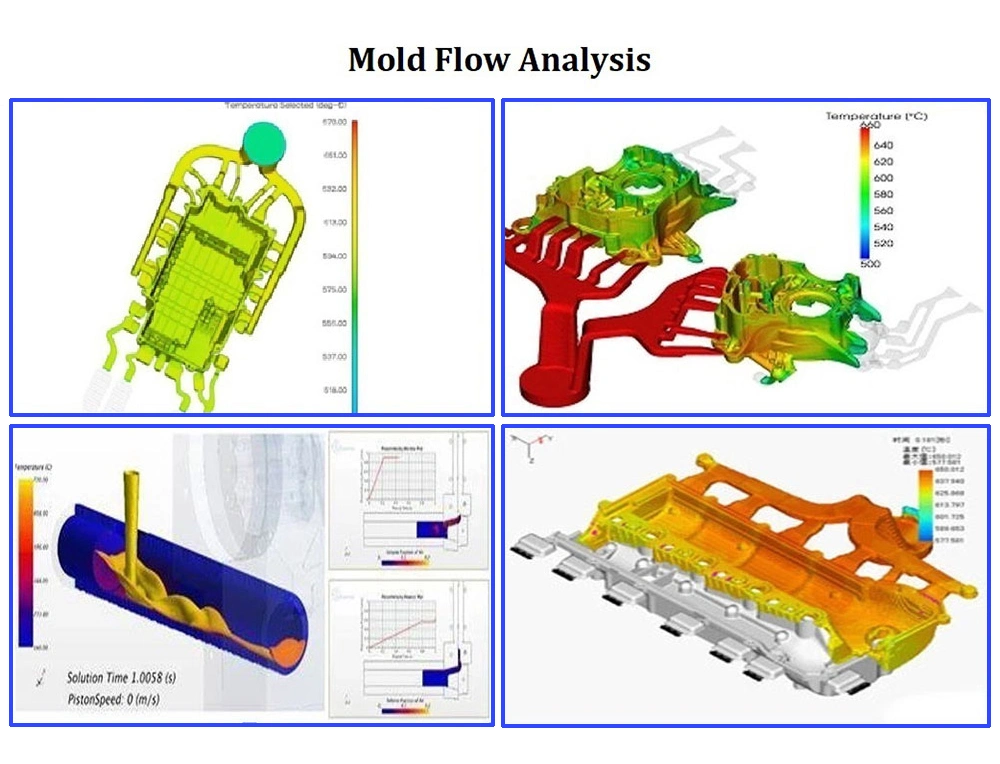

- The latest mold design software and mold flow analysis software

- Complete testing services

- High precision processing equipment

- Strict process control

- Full-dimension inspection by CMM

- Stable material supplier and heat treatment

Quality management system

Quality management systemKangshengyuan is certified for and committed to the ISO 9001:2015 and TS 16949:2016 quality system

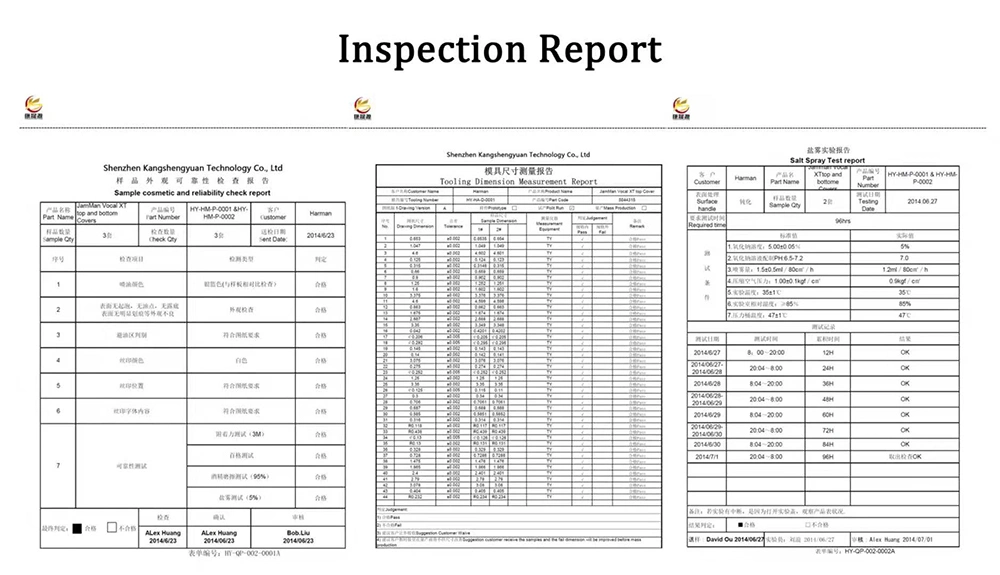

Incoming quality control:

All materials and components are checked upon delivery to ensure that they meet the requirements of each project. All raw materials' certifications are available on request

In-process quality control:

All mold components and parts are checked at each stage of the manufacturing process before being released to the next step. Full dimension inspections are needed for first article

Final quality control

Salt spray test, adhesion test, alcohol test, coating thickness test and so on. We have the most advanced equipments and excellent team to ensure meeting each customer's requirement

FAQ

Q1. Do you offer OEM/ODM service?

Yes.1) Kindly send your drawings or original samples.

2) Please specify the kinds of material and surface treatment.

Q2. Can I put my logo on the product?

Yes, we can silkscreen your logo on the product.

Q3. Can you make my designs?

Yes, OEM/ODM is welcome, feel free to send us drawings.

Q4. How is your lead time?

Tooling : 3-5 weeks

Mass production : 3-4 weeks

Q5. What is your payment method?

Tooling:50% deposit, balance 50%

Mass production: 30% deposit, balance 70% to be paid before shipment.